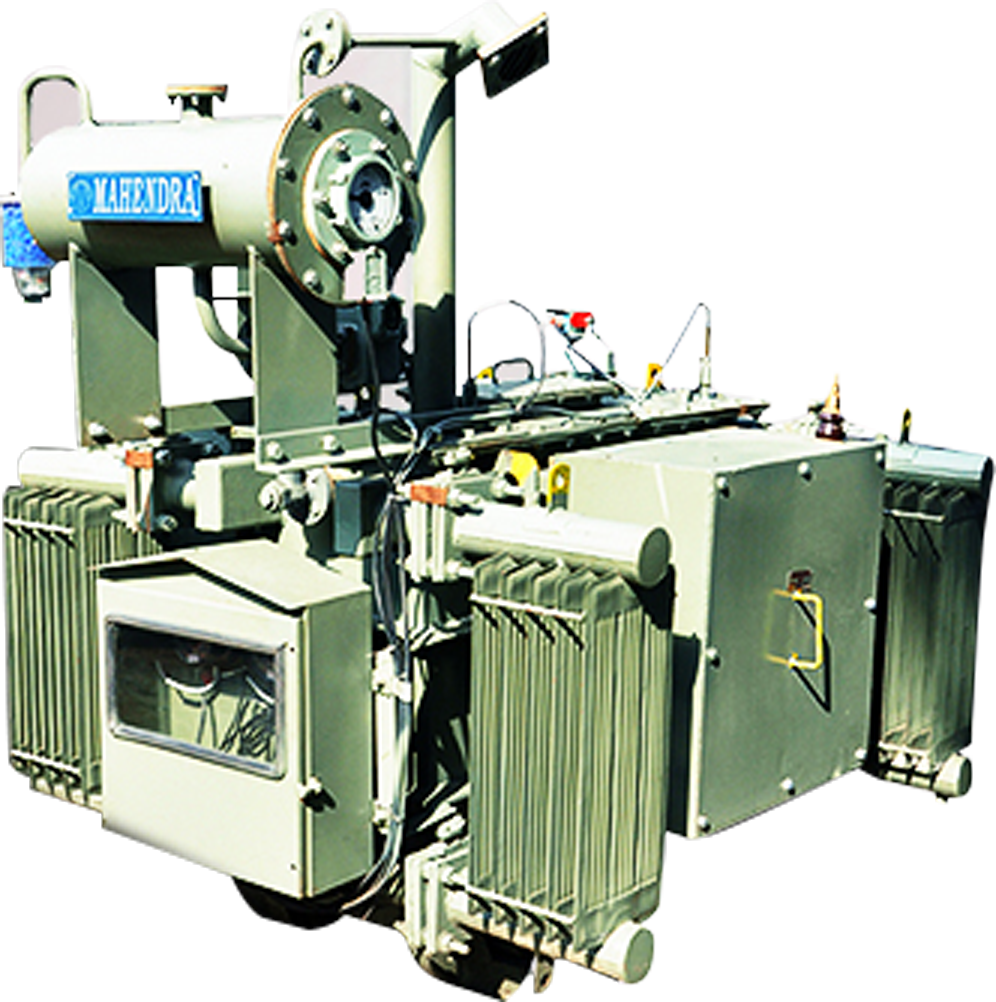

Inverter Duty Transformers are an essential element in the electrical grid of renewable energy power generation. These transformers, while performing the basic function of stepping up and down in voltage, are specialized as they work in tandem with the inverter. These have uses in power flow in large electrical systems, like solar panels, or comparatively smaller circuits, such as a UPS system. The Inverter Duty Transformer Manufacturers in India, like Mahendra Transformers, provide these necessary transformers for power distribution in various residential, commercial, and industrial spaces. Many utility companies partner with these manufacturers for the long term, given that every transformer requires regular inspection and periodical repair works for high longevity and seamless function. Let’s explore the need for the inverter duty transformer, its types, features, and its quality-controlled manufacturing process.

Why Inverter Duty Transformer is Needed

The power produced by solar panels or modules is in the form of DC voltage. But for domestic, commercial and most industrial settings, which are end consumers of the power supply grid, AC voltage is feasible. Therefore, the inverter duty transformers are used to supply electricity suitably at the consumer end from the solar power generation unit. It may be a step-up or step-down transformer. The stepping up process is when the power generated is huge, and needs to be stepped up so that it can be transmitted over long power lines. The step-down transformer is used when power needs to be distributed from the solar panel system.

When high DC power is generated from a solar power system, the inverter converts it into high-voltage AC power. The transformer steps down to a manageable low voltage for low tension applications in the distribution networks. This is how an inverter duty transformer works. In case the low voltage power and high current are received by the primary windings of the transformer, the step-up transformer is used. Though Inverter Duty Transformers Manufacturers in India mostly provide step-down type because of the higher demand.

Types of Inverter Duty Transformer

1. According to Phases

- Single Phase: The single-phase inverter duty transformer supplies power in a single direction, meaning it converts from one voltage level to another. The applications include common residential uses and low-voltage commercial needs. It has a simpler construction and is used in single-phase power needs.

- Three Phase: This has a more complex design, since the power is distributed in three-phase AC and needs more windings and cores in the transformer. The applications of this include large industrial operations and commercial spaces. These have special features like managing harmonic distortions produced by inversion. It can efficiently distribute in large networks and handle higher load requirements.

2. According to Power Supply

- Power Transmission: The power transmission type of inverter duty transformer is the one that steps up the voltage received from the power generation grid, which in this case is the solar power plant. By stepping up, it can send the low current over longer distances.

- Power Distribution: The power distribution type is a more common one in the case of solar panels, because these are more frequent in local power distribution rather than extra high voltage classes. It steps down the voltage received from the solar power system and efficiently distributes it to domestic, industrial and commercial settings.

Features of Inverter Duty Transformer

Inverter Duty Transformers Manufacturers in India include advanced features in these transformers for reliable power distribution at the consumer’s end. These features are:

- The prime advantage is that using solar energy reduces the dependence on conventional fuels, which saves scarce natural resources.

- It can withstand stressful environmental conditions and high operating temperatures.

- Minimizes the harmonic distortions produced in the three-phase inversion

- The galvanic components help shield from electrical faults and isolate the system to prevent damage from overvoltages, arcing, and corona discharge.

- Prevents variation in frequencies and has features like zero-voltage cut off and voltage switching.

- Zero greenhouse emissions due to the absence of biofuels or hydrocarbons

- Supreme regulation against current imbalances, protecting the precious industrial equipment.

Best Inverter Duty Transformers Manufacturers in India

Mahendra Transformers is one of the best Inverter Duty Transformers Manufacturers in India. We provide this in a step-down variant to meet the high demands of our clients needing these for domestic, industrial and commercial places. The voltage ratio of these transformers is standard, i.e, 11kv/433v, though it can be customized as per our client’s specific requirements. These are approved by the highest electrical authorities, adhering to their standards and exceeding their various tests. We use highly advanced machinery to make our transformer, which includes CNC machines and other cutting-edge solutions. For maintaining quality control throughout our manufacturing and before delivery, we use high-voltage testers, insulation resistance testers, and partial discharge testers.

For the exceptional features, quality-controlled manufacturing, and highly versatile applications, our inverter duty transformers stand out.